T: +86-18757377085

+86-18357372880

NO.699 YANSHAN ROAD LIULI,GANPU,HAIYAN,ZHEJIANG,CHINA

In the delicate arena of automobile parts processing, every link is like a severe test. Today, let us walk into the production workshop of an automobile processing company to explore how CHTOOLS solid carbide drill bits stand out in this test.

In the field of steel structure processing, the current profit is relatively low, so cost control is the key. At present, many companies in the market use imported internally cooled twist drills, but their prices are skyrocketing, the procurement cycle is so long that people are eager to wait, and t

现场信息On-site information立式加工中心Vertical machining center型号:Model VC1055数控系统:CNC system FANUC冷却压力:Cooling pressure 20bar材料信息Material Information材料牌号:Material grade A105材料硬度:Material hardness HB204加工厚度:Processing thickness 34mm (17×2 Stacked叠层)刀具信息Tool information刀具类型:Tool Type S钻CPA-P2钻

A spotting drill is a specialized tool used in machining operations, particularly in drilling applications. Here is a detailed guide on how to use it effectively: 1. Equipment Setup - Select the appropriate spotting drill bit according to the material of the workpiece and the required hole diameter.

The advantages of step drills are as follows: Firstly, they have high processing efficiency. They can complete drilling of various diameters in one drilling operation, reducing the number of times to change drill bits and saving time. For example, when processing parts with requirements for multiple

| Color: | |

|---|---|

| Material: | |

| Availability: | |

| Quantity: | |

DNHC-40450

CHTOOLS

Product name | Annular cutter | ||

Model | DNHC | ||

Shank type | universal shank ( weldon shank, Fein shank all shank types are available ) | ||

Diameter | 12-65mm ( customization avilable ) | ||

Cutting depth | 25/50/75/100mm | ||

Packing | Plastic tube | ||

Applicable material | Various steel material, steel plate, stainless steel, aluminum, brass, cast iron, etc. | ||

Applicable machine | suitable for all the magnetic drilling machines | ||

Cutting depth(mm) | Diameter(mm) | Pilot pin(mm) | |

25 | φ12-65 | DPB 6.34*77 | |

50 | φ12-65 | DPB 6.34*102 | |

75 | φ18-65 | DPB 7.98*130 | |

100 | φ18-65 | DPB 7.98*160 | |

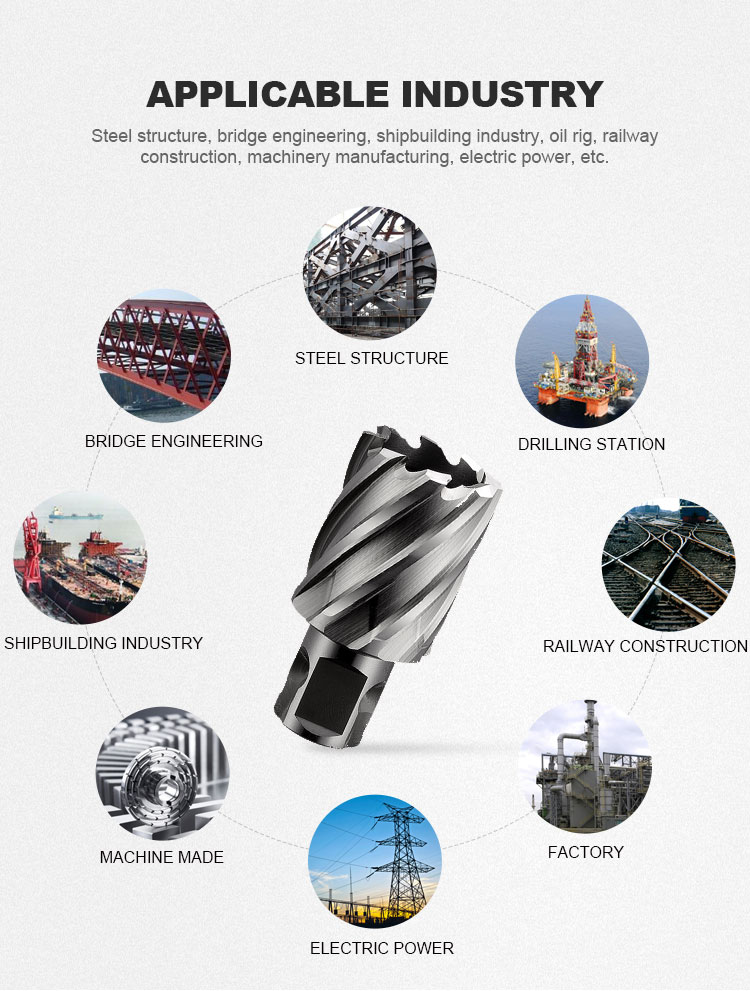

CHTOOLS HSS hole cutter has a wide range of application fields that can meet the needs of various industries and scenarios. CHTOOLS HSS hole cutter has a wide range of application fields, including but not limited to:

Woodworking

It is commonly used in woodworking, such as making furniture and carving.

Metalworking

It can be used for metal cutting and drilling, such as making metal parts and welding.

Plastic processing

It can be used for plastic processing, such as cutting and drilling, to produce plastic products.

Agricultural machinery

It can be used for agricultural machinery, such as tractors and agricultural implements, to make holes for attachments and tools.

Construction machinery

It can be used for construction machinery, such as excavators and cranes, to make holes for various components and accessories.

Zhejiang Xinxing Tools Co., Ltd. is a leading manufacturing and trading company in the hardware tools industry. We are dedicated to producing high-quality tools and providing excellent service to our customers.

With years of experience and expertise, Xinxing Tools specializes in the manufacturing of engineering cutting tools such as steel plate drills, magnetic base drills, hole saws, step drills, chamfering cutters, and rail drills. We also excel in producing high-precision tools like shovel drills and S taps.

At Xinxing Tools, we believe in the power of innovation and continuous improvement. Our team of skilled professionals is committed to developing and delivering cutting-edge tools that meet the ever-evolving needs of our customers. We invest heavily in research and development to ensure that our products are at the forefront of technology and provide the highest level of performance and durability.

Our company prides itself on its strict quality control standards. We have implemented a comprehensive quality management system that encompasses every stage of the production process. From sourcing the finest materials to conducting rigorous testing, we ensure that each tool that leaves our facility meets the highest standards of quality and reliability.

Customer satisfaction is our top priority at Xinxing Tools. We strive to build long-lasting relationships with our clients by providing them with exceptional products and outstanding customer service. Our dedicated sales team is always ready to assist customers with their inquiries and help them find the perfect tool for their specific needs.

We are proud to serve a wide range of industries, including construction, manufacturing, automotive, and more. Our tools have been widely recognized and trusted by professionals worldwide for their superior performance and durability.

As a socially responsible company, Xinxing Tools is committed to sustainable manufacturing practices. We strive to minimize our environmental impact by implementing energy-efficient processes and using eco-friendly materials whenever possible.

In conclusion, Zhejiang Xinxing Tools Co., Ltd. is a reputable company that is dedicated to providing high-quality tools to professionals in various industries. With our commitment to innovation, strict quality control, and outstanding customer service, we aim to be the preferred choice for all your tooling needs. Choose Xinxing Tools and experience the difference in quality and performance.

Product name | Annular cutter | ||

Model | DNHC | ||

Shank type | universal shank ( weldon shank, Fein shank all shank types are available ) | ||

Diameter | 12-65mm ( customization avilable ) | ||

Cutting depth | 25/50/75/100mm | ||

Packing | Plastic tube | ||

Applicable material | Various steel material, steel plate, stainless steel, aluminum, brass, cast iron, etc. | ||

Applicable machine | suitable for all the magnetic drilling machines | ||

Cutting depth(mm) | Diameter(mm) | Pilot pin(mm) | |

25 | φ12-65 | DPB 6.34*77 | |

50 | φ12-65 | DPB 6.34*102 | |

75 | φ18-65 | DPB 7.98*130 | |

100 | φ18-65 | DPB 7.98*160 | |

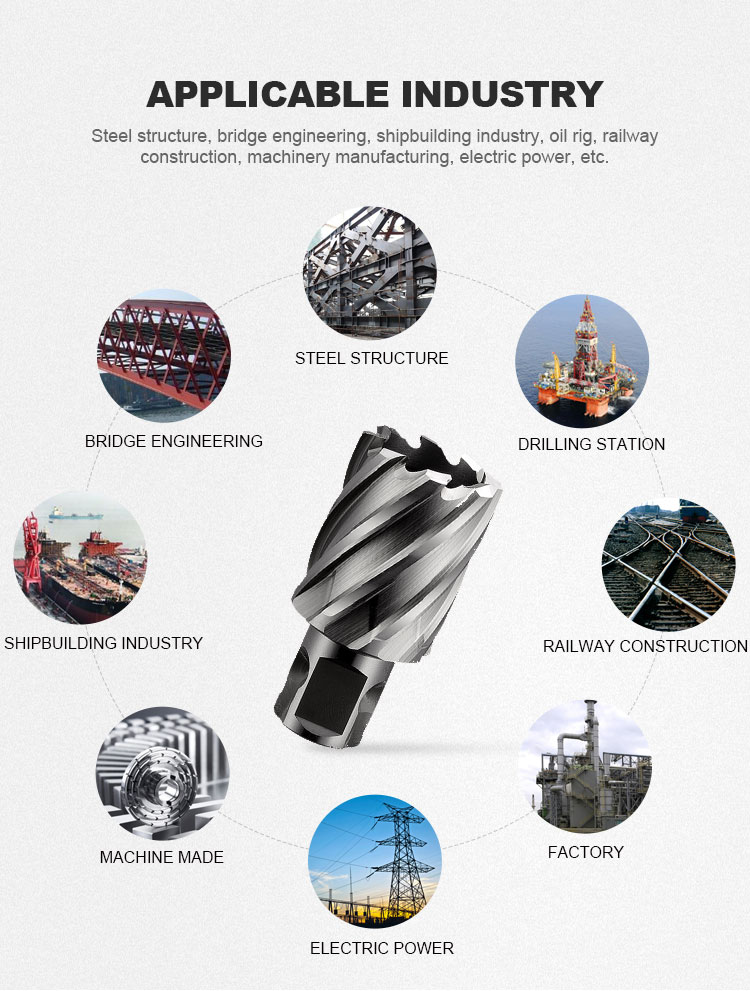

CHTOOLS HSS hole cutter has a wide range of application fields that can meet the needs of various industries and scenarios. CHTOOLS HSS hole cutter has a wide range of application fields, including but not limited to:

Woodworking

It is commonly used in woodworking, such as making furniture and carving.

Metalworking

It can be used for metal cutting and drilling, such as making metal parts and welding.

Plastic processing

It can be used for plastic processing, such as cutting and drilling, to produce plastic products.

Agricultural machinery

It can be used for agricultural machinery, such as tractors and agricultural implements, to make holes for attachments and tools.

Construction machinery

It can be used for construction machinery, such as excavators and cranes, to make holes for various components and accessories.

Zhejiang Xinxing Tools Co., Ltd. is a leading manufacturing and trading company in the hardware tools industry. We are dedicated to producing high-quality tools and providing excellent service to our customers.

With years of experience and expertise, Xinxing Tools specializes in the manufacturing of engineering cutting tools such as steel plate drills, magnetic base drills, hole saws, step drills, chamfering cutters, and rail drills. We also excel in producing high-precision tools like shovel drills and S taps.

At Xinxing Tools, we believe in the power of innovation and continuous improvement. Our team of skilled professionals is committed to developing and delivering cutting-edge tools that meet the ever-evolving needs of our customers. We invest heavily in research and development to ensure that our products are at the forefront of technology and provide the highest level of performance and durability.

Our company prides itself on its strict quality control standards. We have implemented a comprehensive quality management system that encompasses every stage of the production process. From sourcing the finest materials to conducting rigorous testing, we ensure that each tool that leaves our facility meets the highest standards of quality and reliability.

Customer satisfaction is our top priority at Xinxing Tools. We strive to build long-lasting relationships with our clients by providing them with exceptional products and outstanding customer service. Our dedicated sales team is always ready to assist customers with their inquiries and help them find the perfect tool for their specific needs.

We are proud to serve a wide range of industries, including construction, manufacturing, automotive, and more. Our tools have been widely recognized and trusted by professionals worldwide for their superior performance and durability.

As a socially responsible company, Xinxing Tools is committed to sustainable manufacturing practices. We strive to minimize our environmental impact by implementing energy-efficient processes and using eco-friendly materials whenever possible.

In conclusion, Zhejiang Xinxing Tools Co., Ltd. is a reputable company that is dedicated to providing high-quality tools to professionals in various industries. With our commitment to innovation, strict quality control, and outstanding customer service, we aim to be the preferred choice for all your tooling needs. Choose Xinxing Tools and experience the difference in quality and performance.